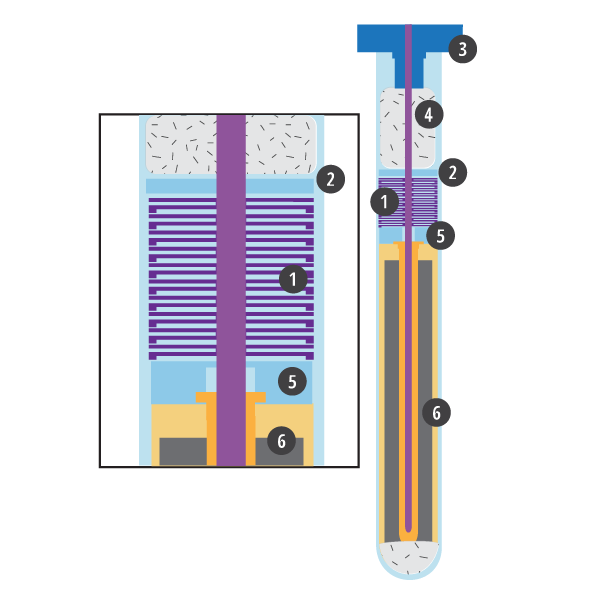

Pond Engineering's Primary Fixed Point Cells (Indium, Tin, Zinc, Aluminum and Silver on the ITS-90) combine outstanding precision, repeatability and accuracy with superb durability and ease of use to produce a uniquely convenient, reliable cell. Following the cell geometry described in NIST Technical Note 1265, these cells contain approximately 1.2kg of high purity metal (0.4kg for Aluminum and 1.6kg for Silver) in a machined graphite crucible with a graphite thermowell liner sealed within a quartz glass envelope.

Unique to Pond Engineering's cells is a set of graphite "springs" directly above the crucible. These springs allow the thermowell to float and the crucible to expand more than 1/8" without stressing the envelope. Two glass spacers above the crucible and thermowell liner maintain proper relative positioning of the thermowell liner. Without this precaution, mechanical forces or hydrostatic pressures developed during heating can easily rupture the crucible, thermowell liner, or glass envelope; destroying both cell and thermometer.

The outer envelope extends approximately four inches above the sealed portion of the cell and is fitted with several layers of ceramic fiber insulation to minimize axial heat loss and keep the cell top cool. A machined aluminum cell top bonded to the envelope enhances durability, suspends the cell in the furnace and accommodates a removable handle. These features ensure safe, easy cell insertion, removal and inspection - particularly helpful when the cell must be removed from the furnace to initiate a freeze (as with the Tin cell).

Since the defined Freeze Point conditions can only exist at the liquid-to-gas interfaces under one standard atmosphere pressure, our cells are sealed with high purity Argon at one standard atmosphere with the cell at operating temperature. Hydrostatic head corrections applied to the theoretical freezing point temperature compensate for the pressure of the liquid metal at the effective sensing point of the thermometer used in the cell. A user manual included with each cell includes tables and charts characterizing a typical freeze plateau profile and the cell's hydrostatic head correction. The bound report also includes a certificate of metal sample purity.

- SPECIFICATIONS

- KEY FEATURES

-

Metal Sample Purity > 0.999 999 Typical Melt Duration > 10 hours in

Pond Engineering

maintenance systemCell Body Physical Dimensions ≈1.97" (50 mm) dia.

≈18.0" (46 cm) longThermowell Dimensions Quartz Glass

≈0.315" (8.0 mm) dia.

≈16" (406 mm) deepImmersion Depth ≈7.5" (190 mm)

from liquid metal surface to well bottom

≈8.4" (214 mm)

from crucible top to well bottom -

1. Unique graphite "springs" allow the crucible to expand and the thermowell to float without risk of cell breakage inherent in other cell designs. When heated from room temperature to operating temperature, the graphite crucible and thermowell can expand as much as 1/8". The springs safely absorb this expansion while maintaining proper positioning of the crucible and graphite thermowell 2. Quartz glass envelope is sealed at a point above the graphite springs with 1 standard atmosphere of high purity Argon with the cell at operating temperature, maintaining an inert atmosphere at the proper pressure for freeze point realization 3. Aluminum cell top suspends the cell safely in the furnace core and allows safe and easy cell insertion, removal and inspection 4. Ceramic fiber insulation above sealed portion of cell minimizes axial heat loss 5. Quartz glass spacers maintain proper thermowell position and support the entire crucible, even if the cell is inverted 6. High purity sample metal (.999 9 pure) used in all primary cells to ensure long, flat plateaus. Certificate of purity included with each cell