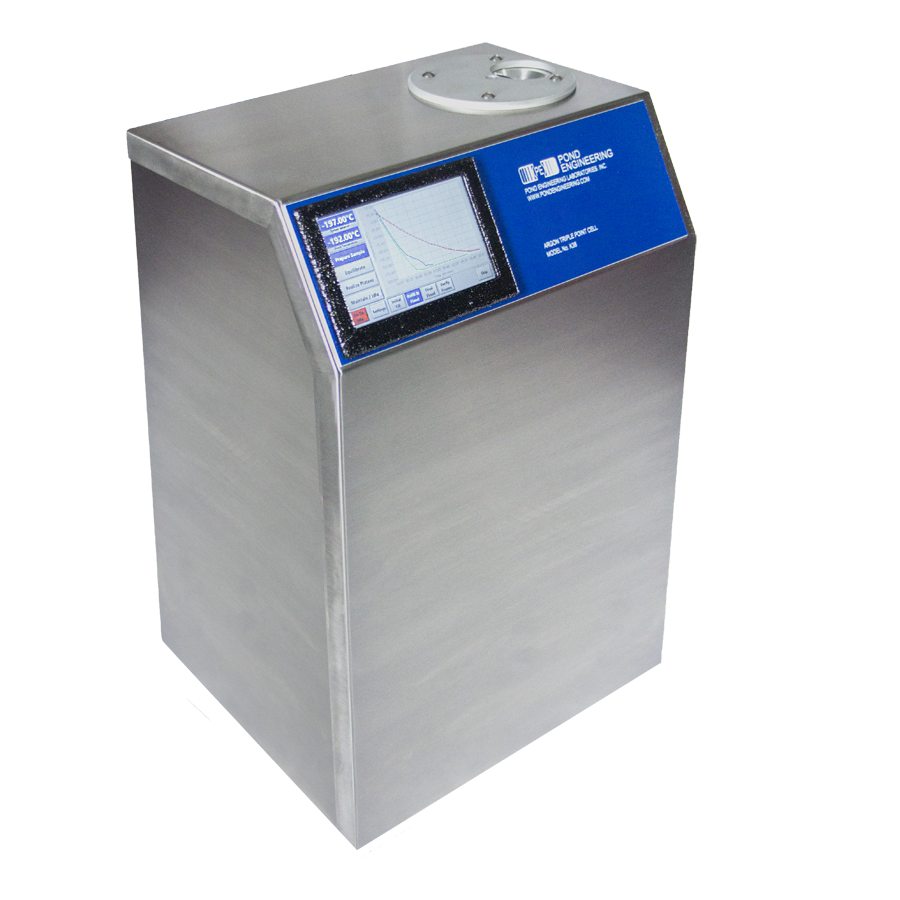

First introduced in 1996, Pond Engineering's integrated Argon Triple Point cell and maintenance system allows users to realize this ITS-90 Fixed Point according to NIST Technical Note 1265 for cryogenic fixed points with an uncertainty better than 0.35 mK when used with quartz envelope long stem or capsule Standard Platinum Resistance Thermometer (SPRTs).

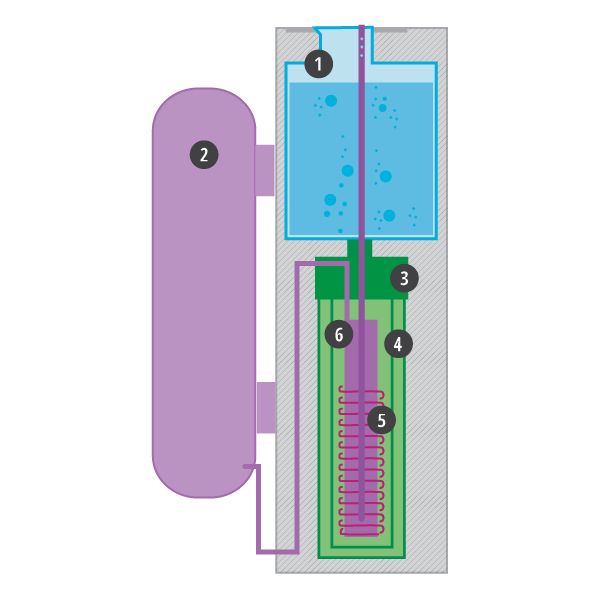

The self-contained system incorporates an internal storage dewar which holds approximately 2.5 L of liquid nitrogen. Once cooled and frozen, the volume of liquid nitrogen in the internal storage dewar is sufficient to realize the triple point and maintain the cell on plateau for several hours. To calibrate multiple thermometers on a single plateau or to extend the plateau, users simply add liquid nitrogen to the internal storage dewar during the maintenance stage.

The sealed cryogenic cell contains approximately 1.7 moles of .999 999 pure Argon. Rapid cool down, freeze and stabilization times coupled with integrated system prompts help users realize the point quickly and easily. Microprocessor-based controls give the user access to realization functions, system setpoints, sensor calibration functions and system variables.

New and improved user interface on a sloping front panel provides convenient system control, along with step-by-step instructions and training on a 5-inch touch screen. Optional remote interface (RS-232 or USB) allows users to integrate the K38 into an automated calibration system. Communication software available for either interface option allows users to monitor and configure the system from any remote computer with a graphical user interface.

Since the defined Triple Point conditions can only exist at the solid-liquid-gas interface under the triple point pressure, a hydrostatic head correction must be applied to the theoretical triple point temperature to establish the temperature at the effective sensing point of the thermometer used in the cell. A user manual included with each cell includes data characterizing the cell's geometry and the cell's hydrostatic head correction.

- SPECIFICATIONS

- KEY FEATURES

-

Sample Purity 99.9999% Typical Plateau Duration ≈4 hours on a single fill

of the internal LN2

storage dewarThermowell Type 304 Stainless Steel

≈0.325" (8.2 mm) dia.

≈14.8" (376 mm) deepImmersion Depth ≈5.2" (13 cm) from liquid

sample surface to well

bottomOperator Interface Manual Front Panel

(optional RS-232 or

USB remote interface)Power Requirements 90-264 Volts

1.5 Amps max

A.C. 47 - 63 Hz.Cabinet Physical Dimensions ≈12" (30.5 cm) wide

≈8.5" (21.6 cm) deep

≈18" (45.7 cm) high -

1. Liquid nitrogen contained in an internal storage

dewar provides cooling for cell guard zone and cools thermometer well and stem above cell2. Storage vessel contains high purity Argon sample gas when system warms to ambient room temperature 3. Guard zone provides uniform temperature environment for realizing the Triple Point conditions under computer control 4. Copper shells, thermally anchored to guard zone, minimize thermal radiation to cell; ensuring consistent plateaus 5. Electrical heater on the cell body helps to verify the presence of Triple Point conditions by adding heat pulses to the cell, under internal computer control, melting small amounts of solid Argon; causing the cell to transition through the melt plateau 6. Physical properties of high purity Argon sample gas realize the actual defining Fixed Point within a sealed cell, rather than simply providing a stable thermal environment for comparison of thermometers