Home / Primary Temperature Metrology / K29H Water Triple Point Cell

K29H “Halo” Water Triple Point Cell

The Triple Point of Water (TPW) is the reference temperature for resistance ratios in platinum resistance thermometry. It is defined to be the temperature of pure water with an isotopic concentration equivalent to that of mean ocean water, with its solid, liquid, and vapor phases in thermal equilibrium. With the redefinition of the SI unit Kelvin in 2018, the TPW is no longer part of the definition of the thermodynamic temperature scale, but remains a defining fixed point on the ITS-90 with an assigned value of 273.16 K (.01°C t90). Practical realizations of this fixed point must be corrected for hydrostatic head, thermometer self-heating and isotopic composition effects. The easiest to use and most cost-effective of all the defining fixed points, the TPW cell provides the lowest uncertainty achievable for calibration of precision thermometers of many types.

The Pond Engineering Model K29H “Halo Cell” represents a significant leap forward in Water Triple Point Cell design, combining enhanced long-term temperature stability with a more durable, shippable design.

The patented design of the Halo Cell provides a means for the user to re-distill the water sample at any time by transferring substantially all of the water sample into the upper volume of the cell - the “halo”. By simply returning the cell to its normal orientation and immersing the cell body in a maintenance system, the water sample is re-distilled, leaving behind any impurities it may have contained, including any that may have leached into the water from the glass envelope over the lifetime of the cell.

When properly prepared for transport and packaged, the Halo Cell can also be safely shipped via popular small-package delivery services. Once the water sample has been transferred to the halo, the unique, patented transfer tube geometry prevents transfer of water back into the cell body REGARDLESS OF PACKAGE ORIENTATION. With the water sample contained in the halo, the packaged cell can be shaken, dropped, and shocked in any direction without creating the devastating water hammer that is so destructive when attempting to ship other cell types.

Similar to the portion of the glassware extending above the top of type A cells (the "handle"), the halo of the K29H contains internal features that form a McLeod Gauge, used to indicate the presence of non-condensible gases in the cell. This allows the user to verify the integrity of the cell envelope throughout the lifetime of the cell.

Pond Engineering constructs the Halo Cell of high-quality borosilicate glass with a 13mm diameter thermowell. Following thorough cleaning of the cell interior, the cell is evacuated, filled with ultra-pure degassed water, and flame sealed. Isotopic concentration analysis is performed on the water used to fill the cells after the degassing process is complete. The results of this analysis are used to calculate an isotopic composition deviation correction provided with each cell. Water samples for independent isotopic analysis can be provided with each cell upon request at the time of order placement.

Uncertainty, reproducibility and stability of the temperature realized in a TPW Cell are nothing short of phenomenal. Pond Engineering TPW Cells are guaranteed to realize a temperature within +0.0000, -0.0001 K of the theoretical defined TPW after correction for hydrostatic head, thermometer self-heating and isotopic composition.

Low-cost maintenance systems like Pond Engineering’s K29D make TPW cells more efficient than conventional ice baths, even for routine calibration work.

- Sample Purification

- Cell Transportability

-

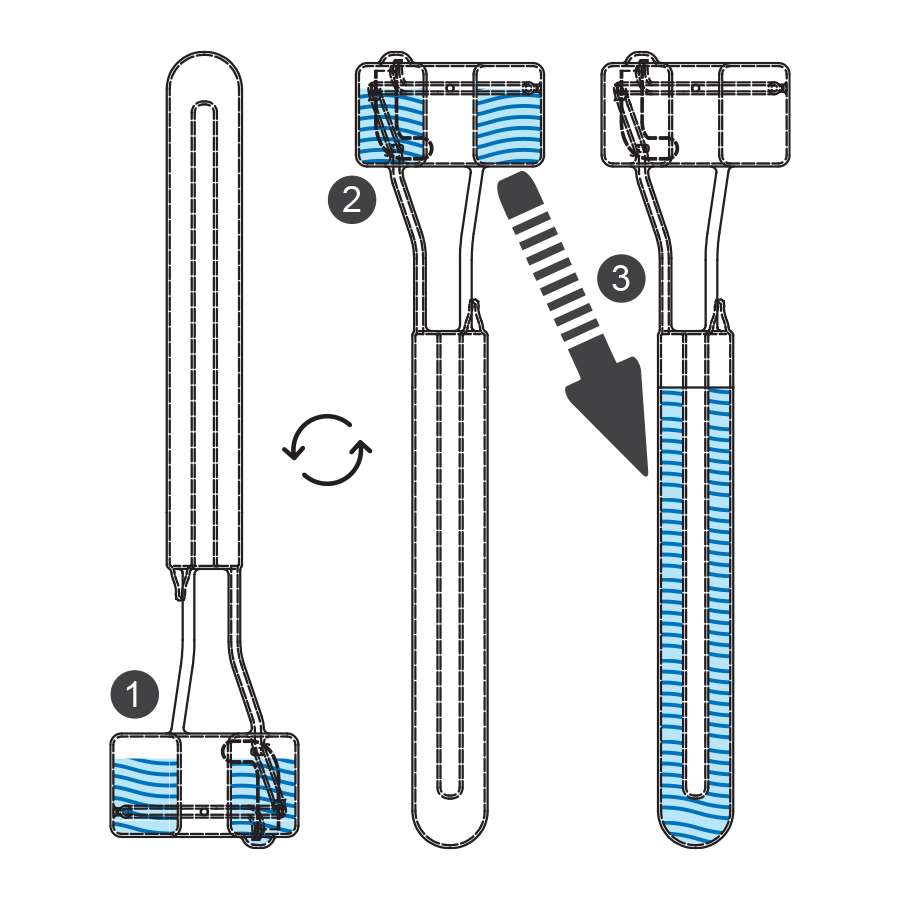

High-purity water is extremely aggressive and is capable of dissolving components of the cell envelope (quartz or borosilicate glass) over time, contaminating the sample water and resulting in long-term drift of the realized temperature. The Halo Cell eliminates this drift by providing a way to periodically purify the sample water by sub-boiling distillation. 1. The sample water is prepared for purification by simply inverting the cell, causing the sample water to transfer from the cell body to the halo through the interconnecting tube. 2. Following a series of specific motions, the cell is returned to its normal orientation while keeping the sample water in the halo. 3. Immersing the cell body in a conventional maintenance system begins the purification process by drawing water vapor from the halo into the cell body where it condenses, leaving soluble impurities in the halo. This restores the water sample purity in preparation for the next TPW realization. -

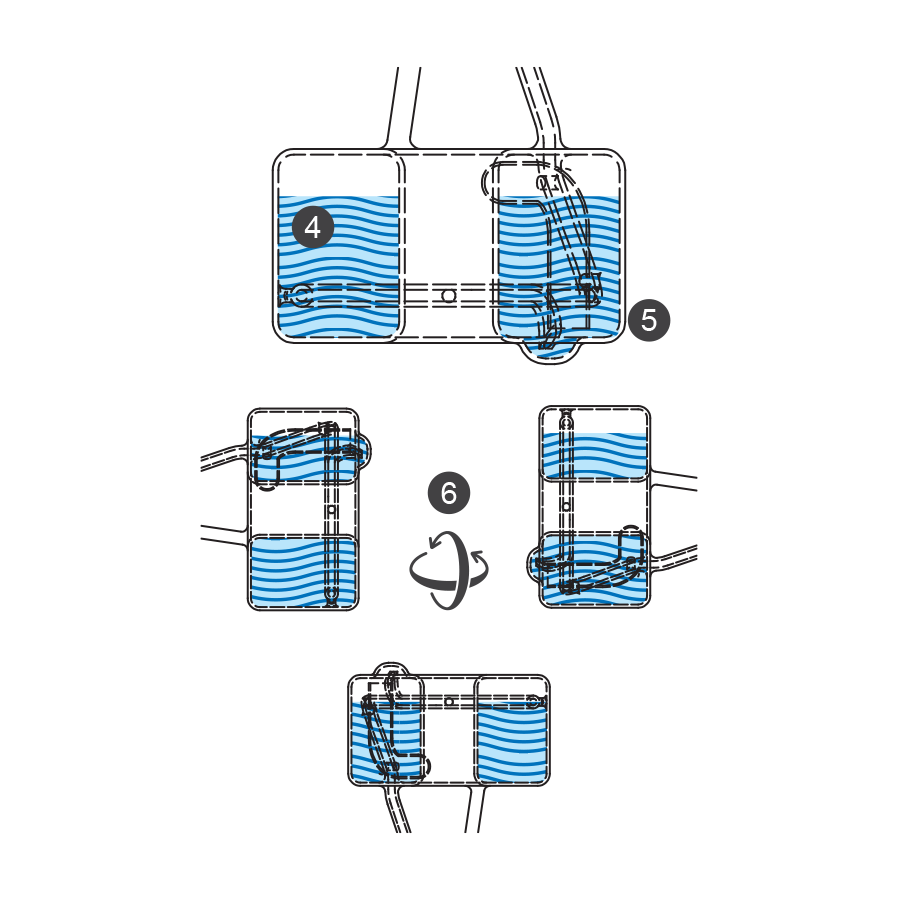

Transporting TPW cells has long been a problem, frequently resulting in destruction, primarily from internal water hammer. The resultant loss of a primary standard and its calibration history can be devastating. Hand-carrying cells to and from national laboratories has been effective for some, but is becoming increasingly difficult in today’s world. The Halo Cell provides a solution that can be routinely packaged and shipped with confidence. 4. The Halo Cell is prepared for shipment by inverting the cell and transferring the sample water into the halo through the interconnecting tube. 5. The patented Halo Cell design isolates the sample water in the halo during shipment. The unique length:diameter ratio of the halo eliminates the potential to create a destructive water hammer, allowing the cell to be safely shipped via popular small-package delivery services. 6. The unique, patented geometry of the sample transfer tube prevents significant water transfer during shipment,REGARDLESS OF PACKAGE ORIENTATION .

When used with Pond Engineering's Model K29D Water Triple Point Cell Maintenance System, the mantle can be maintained virtually indefinitely with minimal operator time.

The Halo Cell Technology is protected by U.S Patents: #10,768,056 & #10,876,905