Previously utilized as a secondary fixed point, the melting point of Gallium has been assigned a temperature of 302.9146 K (29.7646 °C) and adopted as a defining fixed point on the International Temperature Scale of 1990 (ITS-90). And Pond Engineering has designed a user-friendly, high-performance system to realize it.

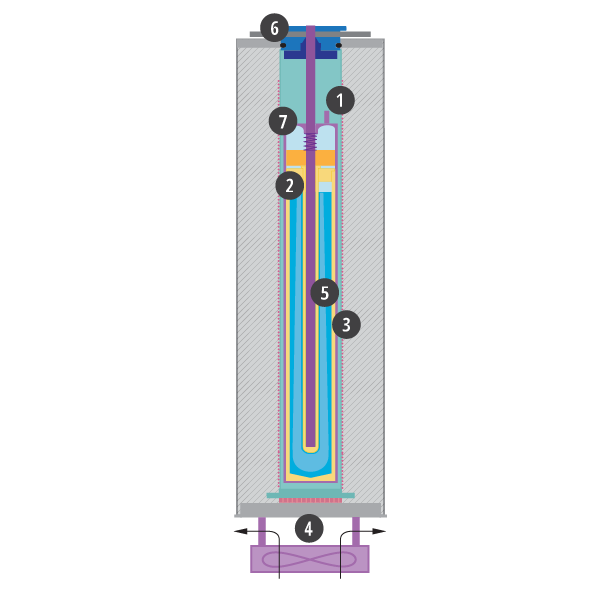

Following the geometry presented in NIST Technical Note 1265, our model K28C Gallium Melting Point cells contain approximately 1 kg of .999 999 9 pure Gallium sealed in an inert plastic crucible and surrounded by a durable welded stainless steel envelope. This construction easily accommodates the approximate 3% expansion of the freezing Gallium, while maintaining the required 1 standard atmosphere pressure of high purity Argon gas surrounding the metal sample. Welded Type 304 Stainless Steel removes the risk of cell breakage in normal use and the high purity metal sample produces a remarkably stable, long-lasting temperature plateau. Typical melt plateau variations are less than .0002°C over 24 hours.

The Model K28M Maintenance System safely and easily puts all the functions necessary to realize the Gallium Melting Point literally at the user's fingertips. An integrated two-zone controller provides the user positive control of axial gradients within the cell and allows the cell to be frozen from the bottom upward; the best way to prepare a cell for storage.

Interactive user interface on a sloping front panel provides convenient system control in a stand alone configuration. Standard features include a universal input power supply operating with a total power input of less than 50 watts for versatility and safety.

Platinum Resistance Thermometers (PRTs) with 20-bit A.C. excitation resistance ratiometric signal conditioning used (instead of thermocouples) for all temperature sensing provide unprecedented accuracy and control stability. Interactive internal system temperature sensor calibration functions allow users to maintain system performance over time.

The Gallium point is the easiest to use and most reliable of all the metal fixed points on the ITS-90. The combination of Pond Engineering's K28C and K28M systems provides an affordable, durable, accurate and usable system ideal for realizing this crucial point.

- SPECIFICATIONS

- KEY FEATURES

-

System Setpoint Range 15°C to 38°C Control Stability Better than +/- 0.02°C Core Gradients Less than +/- 0.05°C Setpoint Accuracy Better than +/- 0.05°C Main Well ≈1.49" (37 mm) I.D.

≈14.4" (36.6 cm) deepPower Requirements 85 to 265 Volts

1.0 Amps max.

A.C. 47-63 Hz.Cabinet Physical Dimensions 18" (46 cm) wide

20" (51 cm) deep

36" (92 cm) highCell Dimensions

Body

Thermometer Well

Immersion Depth

≈1.46" (37.3 mm) dia.

≈11.5" (29.2 cm) long

≈0.32" (8.2 mm) I.D.

≈12.8" (32.5 cm) deep

≈7.9" (200 mm)Sample Metal 1 kg. Gallium

.999 999 9 Purity -

1. Welded stainless steel cell envelope provides a completely sealed cell, one not affected by atmospheric pressure changes, nor prone to breakage in normal use 2. Inert plastic cell and thermowell liner contains the Gallium metal sample and absorbs the pressure accompanying the approximate 3% expansion of the freezing Gallium 3. Isothermal Zone provides an ideal environment for maintenance of the Gallium Melting Point. Typical plateau duration exceeds 24 hours 4. Solid state thermoelectric module cooling system provides positive control of axial gradients and ensures that the cell is frozen from the bottom upward 5. High purity Gallium (99.99999%) provides exceptionally flat plateaus 6. Removable cell top suspends the cell in the isothermal zone, and allows for easy insertion, removal, and inspection 7. Cell body is construced of machined stainless steel components, ensuring a completely smooth interior surface which minimizes possible contamination of the high purity metal